Shifting bridges

Spectacular success for HOCHTIEF engineers on the A 45 highway: At the beginning of March 2021 they managed to achieve something that had never been done before in Germany: They slid a bridge that is almost 1,000 meters long. Look over the shoulders of our engineers Lars Scheidemantel and Yannis Schwarze on their big day.

On this page

Three Eiffel Towers on the move

That was the pinnacle in the new construction of the Lennetal Bridge near Hagen in North Rhine-Westphalia. Never before has a bridge this long been slid sideways in Germany. A 30,000 tons-colossus, three times as heavy as the Eiffel Tower.

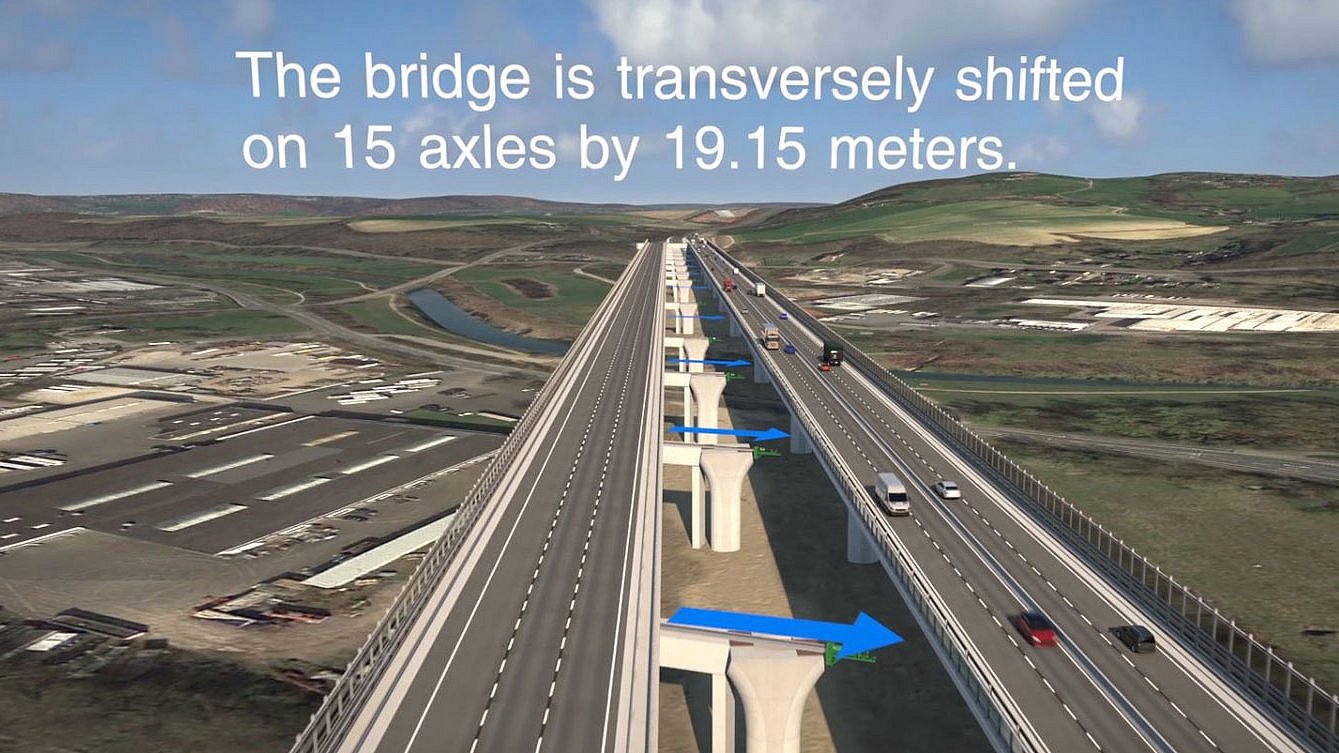

Hydraulically driven steel cables moved the structure by exactly 19.15 meters to the new columns. The operation, which had been planned for months, lasted for 6.5 hours, while traffic continued right next to it. We had to proceed extremely carefully, so that the concrete does not crack. This type of operation cannot be done by force, says project manager Jan Felgendreher. A team of 70 specialists made sure that the operation succeeded. Traffic was approved on the whole bridge in summer 2021.

The bridge in figures

A single 30-ton truck with four axes damages the road more than 60,000 conventional passenger cars.

Number of vehicles which drive across the structure every day.

Number of major bridges which have to be replaced just on the 100 kilometer long section between Schwerte and Siegen.

The structure can travel 3 meters per hour, about as fast as a Roman snail.

Quantity of truck loads of concrete which were required for the new construction.

he structure measures so many meters, to be precise.

The path to the premiere

An “open-heart” operation—and a challenge for bridge construction experts. To ensure that the traffic can continue to flow, our experts demolished the existing bridge and replaced it by two new bridges, one for each traffic direction. In order to be able to demolish the old bridge, an auxiliary bridge was first built to accommodate the traffic. Step 2: The old Lennetal Bridge was demolished, and two new bridges were built, but for one of them only the columns were built. At the beginning of March 2021 the roadway of the auxiliary bridge was slid sideways onto the new columns.

Impressions from the construction period

Our man on the bridge

-

Yes, I’ll do it

Jan Felgendreher clearly remembers the moment when he first talked with his former boss about the Lennetal Bridge...

...He was desperately looking for a project manager for the major bridge project. This conversation proved to be trendsetting. “Yes, I’ll do it” was Felgendreher’s answer.

Hesitating, having reservations, hedging his bets before he takes the next step—you can imagine Jan Felgendreher as really quite the opposite of this. A guy like a tree—frank, hands-on, straightforward. “Yes, I’ll do it”, was also his reaction when HOCHTIEF hired him as a site manager after he finished studying engineering in 1996, and on the very first day of his professional life he was able to participate in building the B9 road tunnel in Bad Godesberg. “I have never regretted it”, says Felgendreher after a quarter of a century at HOCHTIEF. “Every day I learn something new and I am constantly amongst people from very different constellations. The 52-year-old has experienced a great deal, for instance the construction of Terminal 2 at Cologne/Bonn airport and several lignite and refuse-fired thermal power plants.

He recruited many up-and-coming engineers for the Lennetal Bridge. “That’s really enjoyable.” And, in his pleasant but blunt way, right from the outset he spells out what he expects from those who are intended to take over from him in managing projects: “On the construction site you have to have fun and work your butt off, so that clients, bar benders and Executive Boards are satisfied.”

What is necessary for this, appears to be a healthy portion of humility. “Every leader should have children. They will demonstrate your limits.” Felgendreher has two sons who went to school in England, because until 2012 he worked eight years there for HOCHTIEF. In order to avoid jeopardizing the drinking water supply in Brighton in Southern England, he had to pump water underneath a concrete basement measuring 60 times 60 meters to “float” it and move it 60 meters. So he is well acquainted with the pitfalls of transverse moving in large-scale projects.

As the sons recently rather anxiously asked him if he really wanted to get involved in completing the construction of the Leverkusen A1 highway bridge, he showed them that it was OK to take up challenges. The HOCHTIEF man answered briefly and conclusively: “Naturally.”

Knocked down

“That is really fun.” Project manager Jan Felgendreher can well remember the loud bangs in 2017. Explosives knocked down the Lennetal Bridge, which had been built in 1967—Felgendreher’s first demolition. “When the blast rang out I dropped my cellphone.” Clouds of dust enveloped the valley, before finally clearing to reveal a view of the concrete that had crashed to the ground as planned. The columns standing on both sides of the railway line also collapsed in the envisaged direction.

Unhindered flight for bats

The work on the new Lennetal Bridge at a height of between 20 and 30 meters above the River Lenne was intended to have as little impact as possible on the natural environment This amongst other things benefited the bats, for whom HOCHTIEF built a four meter long tunnel on a slope, so that the bat populations anticipated there would remain undisturbed. HOCHTIEF also made the partly rigid bank of the River Lenne more flexible and hence more natural. Specialists call this bank renaturalization.

Several tons of rubble were created by the demolition of the bridge. The material was sorted and recycled. Some of it was taken to the site of the former Opel automobile plant in Bochum, where it served as the basis for the new industrial park. HOCHTIEF recycles concrete rubble to use in the foundations of other bridge projects.

Project manager Jan Felgendreher believes the bridge itself is particularly sustainable because it is designed to last for 100 years.

By the way

-

“Queen of the Highways”

That is what they call the “Sauerlandlinie” because of its beautiful curves and ups and downs and impressive valley bridges.

-

Slightly tinged but not rusty

According to experts that is the best condition for steel for a transverse sliding, over which the bridge was moved with the aid of hydraulic fat, Teflon and Elastomer after comprehensive tests.

-

The concrete lives and thinks in centimeters, the structural steel engineering and the transverse sliding technology in millimeters

Project manager Jan Felgendreher knows that every small detail matters during the transverse sliding of the bridge measuring almost a kilometer.

Highways subjected to heavy load

Old structures have to go

The Lennetal Bridge is not the only ailing structure. Leverkusen’s A1 highway Rhine Bridge, Schiersteiner Bridge near Wiesbaden, the A40 highway bridge near Duisburg… The list is almost endless. At many places the highway network is groaning under the daily burden of trucks. For many years too little money was invested in maintenance, and now the wear cannot be overlooked. And some bridges have to go before they are “due to retire”.

Like the Lennetal Bridge. “Actually a pity. Very sleek, engineering masterpiece. But there is no way of avoiding demolition”, says project manager Jan Felgendreher. Reason: In the 1960s the A45 was also regarded as a “holiday highway” which was intended to enable people from the Ruhr region to drive South more quickly. Nobody expected the traffic volume to explode.

More than 10,000 trucks roll across the structure each day. And they are getting increasingly heavy. In 1956, 24 tons were allowed, but today 44 tons. Trucks make the bridge vibrate. Small cracks form in the concrete, through which salt water penetrates and attacks the steel–until the reinforcement rods are rusted through and the concrete crumbles off.